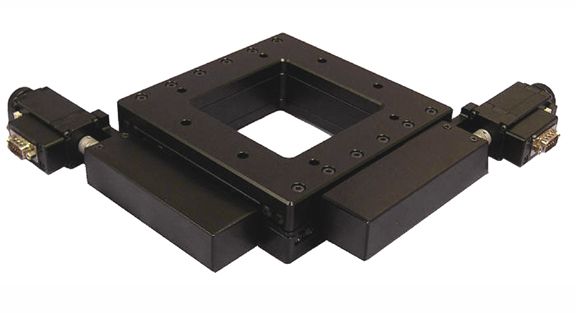

Motion Control – Miniature Linear Focus Actuator

LFA-1007 Linear Focus Actuator: 10mm clear aperture, 7mm range of motion, <50 nanometer positioning resolution, 50 grams moving mass, 70 x 70 x 50 (600g)

Forestville, CA — Motion Control Linear Focus Actuator – The LFA-1007 is a high performance compact positioning actuator. It was specifically developed for applications requiring both high precision and high-speed positioning over a short to medium stroke.